The new high-tech automated mixing system removes human error, sets a new standard for refinish color accuracy, and avoids costly extra materials and labor time

Performing a color mix from a toner system can be challenging while attempting to achieve utmost accuracy and efficiency. For example, a slight error can result in an overpour, requiring the technician to add more material than needed and the time to resolve the mix. Also, to play safe, technicians often mix more product than required to avoid running out of paint during the refinish process. Overtime, the extra cost in paint materials and labor time expended can be significant.

Enter the PPG MoonWalk automated mixing system—a technological advancement that takes human error out of the equation and is setting a new standard for refinish color accuracy.

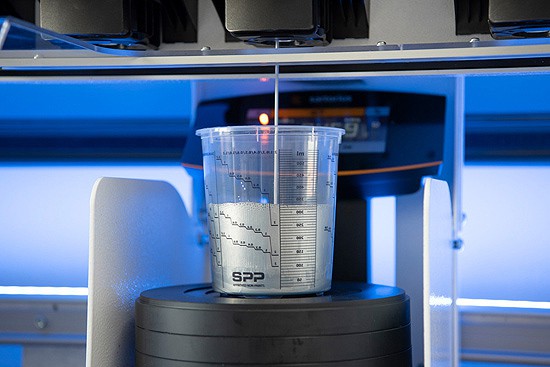

Designed for the PPG ENVIROBASE® High Performance toners, this fully self-contained mixing system is comprised of storage space for toners, a scale, a computer for formula retrieval, a touch screen and label printer.

Creating a color mix is simple and straight forward. Once the technician retrieves the matching formula from PPG’s PAINTMANAGER® XI software, the technician loads the required toners on a dispensing rack. Then, with one click, the PPG MoonWalk system takes it from there. First, it double checks barcodes to ensure the right toners are loaded. The system then automatically dispenses the exact amount of toner with a precision previously unheard of, thanks to the advanced technology that is 10 times more precise than the standard. To further eliminate waste, the system’s unique technology and toner packaging are designed to ensure all of the product is used, down to the last drop.

“There’s going to be a serious paint savings,” states Frank McClosky, owner, McClosky’s Collision Repair, Baytown, Texas. “Each one of those drops costs money and, with the MoonWalk system, one of the most obvious differences is that it mixes to the hundredth—not to the tenth—so it’s much more accurate with the color match. And when the painter has full confidence knowing that the color is going to match the first time, there’s no need to mix extra paint that you might need to tint.”

The PPG MoonWalk system also works seamlessly with the RAPIDMATCH® XI and the PPG DIGIMATCH™ spectrophotometers. After a reading is taken, the technician loads it into the PaintManager XI retrieval system and automated mixing takes over from there. “Once the mix is started, the painter can move on to something else,” adds McClosky.

McClosky sums it up by stating that “I would recommend the MoonWalk system to a shop that was interested in doing the highest quality work that was available to be done and is interested in standardizing their procedures to get more predictable results in the long run.”

The PPG MoonWalk system is also compatible with the color tools of the PPG LINQ™ Digital Ecosystem.

For more information, visit us.moonwalkrefinish.com.

Comments are closed.