Here are the most common misconceptions about training in the aftermarket you should be aware of as you plan for 2024

In 2023, the Today’s Class team had hundreds of conversations with shop owners, technicians, advisors, and trainers from shops of every size, from single locations to enterprise organizations. Throughout those conversations, we heard some recurring themes and misconceptions. Here are the most common misconceptions about training in the aftermarket you should be aware of as you plan for 2024.

Misconception #1: One-Time Training is Enough

The most common misconception is that covering educational material just once is enough. While most shop owners understand that a one-time exposure to a topic won’t lead to mastery, they rarely require their team to revisit the subject. Often, this is because employees push back with, “I already passed that course.”

The mindset of taking a course once, getting a passing grade, and never having to see that content again is the educational approach most of us experience in high school. While that might be fine for a teenager taking a biology class, it doesn’t work for your technician who needs to learn to perform safe service procedures on a hybrid, for example.

Repetition is critical to mastering a craft, automotive service included.

Research supports the importance of repetition in skill acquisition, with spaced repetition proving particularly effective for long-term retention. Shop leadership should consider embracing training that can be done on-site in short intervals, and establish a schedule for material review from courses taken off-site to reinforce learning continually.

Phil Carpenter at Urban Autocare in Colorado told us that although his shop’s technicians enjoy conferences where they participate in breakout sessions over a few days, they report feeling as if they were drinking from a firehose. “Not only that,” said Phil, “if they didn’t go back and review their notes later, they didn’t retain much of what they learned.”

One small step you can take is to set a reminder on your phone to revisit the training with your employee a month afterward. Ask your employee a few questions about the course they completed and provide coaching where needed. Setting this reminder is an easy way to help reinforce your employee’s training and indicate whether or not they’ve retained the information.

Misconception #2: More is Better

Most of the shops we spoke with in 2023 relied on in-person classes as their core training solution. These classes are often expensive and time-consuming, usually requiring a time commitment of many hours (or even a full day or several days) to justify the costs and deliver all the material.

Delivering the information can be difficult for instructors, as they have so much to include. It’s common to hear a trainer start the session with, “Let’s get started; we have a lot to cover.” Due to the volume of material, the instructor must keep a brisk pace that doesn’t leave much time for questions or discussion.

As mentioned previously, drinking from a firehose is a common analogy. Miller’s Law, a common principle in cognitive psychology, suggests that humans can only absorb five to nine items in their working memory at a time. During a three-hour course, there could be 50 to 100 or more relevant or interesting facts that the instructor shares. But if your brain can only absorb 10% of the information, the costs described above can become very difficult to justify.

To be clear, this is not an indictment of instructor-led training but an acknowledgment of how our brains work and what’s realistic based on adult learning research. Instructor-led training could not be cost-justified (by anyone) if the courses were right-sized for Miller’s Law because they’d probably be less than 20 minutes long. Most instructors we work with would love nothing more than to address this limitation of the human brain. In the meantime, they must continue covering as much material as possible in an engaging way to ensure every attendee leaves with more knowledge than they arrived with. Their task is a difficult one.

Misconception #3: The Training You Want is the Training You Need

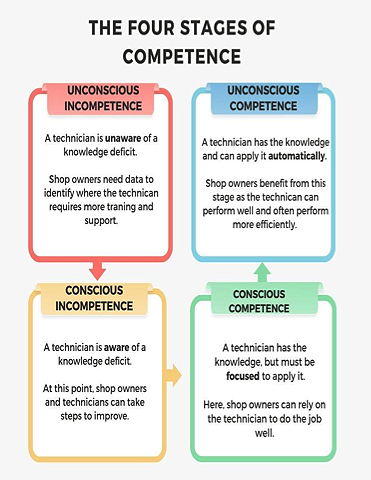

Technicians and service advisors typically take courses to fill a gap in their knowledge or due to interest in the subject. When a manager enrolls an employee in training, the motivations are similar. They may be aware of a knowledge gap or want to offer a new service that requires employee upskilling. These decisions are made because the decision maker consciously knows the learner needs to develop in that topic, what is referred to as conscious incompetence. At this stage, the learner recognizes the need to learn or develop a skill and sets out to do so.

Most aftermarket training decisions are based on assumptions of our knowledge gaps. Historically, these assumptions have been based on observation, personal experience, and opinions — it’s all subjective information.

Instead, organizations can shift from subjective assumptions to objective, data-informed conclusions. Data can come from work order summaries, employee assessments, and learning management systems. The more data you have, the better you can determine your team’s unconscious incompetence, deficits they are unaware of.

Using data to uncover gaps and risks can help you prioritize training efforts and spending. Pairing this data with your business objectives and most common repairs can reframe your training approach. For example, your technicians may want training on dynamic calibration, but the data says your technicians need training on lighting and accessory systems.

Misconception #4: “Free” Training (That Isn’t)

It’s smart to be wary when something is touted as “free.” Regarding training in the aftermarket, there is no shortage of free resources for your team. Many vendors, for example, provide excellent training materials that complement their products or services. But the cost comes in how you can leverage it to make your team better.

It’s certainly possible to get terrific free training on brakes from Vendor A and above-average training on suspension from Vendor B, but the costs can sneak up on you as you try to piece together a “comprehensive” training program. Your time is valuable. How much effort is required to stitch together a training program from the available free resources? What if your training needs are greater than what’s offered? The provider of the free training is unlikely to accommodate those needs, meaning you must spend time and money on another solution.

Another facet to consider in the actual cost of free training is technician motivation — or the lack thereof. Many shop owners told us that when they had access to free training resources, they didn’t lose sleep over their employees not taking advantage of it. Essentially, it didn’t cost the shop owner any money, so no harm was done if no value was derived.

Time after time, we found that shop leaders who wanted to drive value from employee training made the necessary investments to do it. It’s true that they often weave in some of the great, free resources they have — but it was rare for them to lean on free training entirely.

With rapid technological advancements, training models must change to keep pace. Microlearning, gamification, and spaced repetition of short training sessions can help get your team up to speed in the most time- and cost-effective manner. If you have questions about adult learning and how it applies to training in the auto aftermarket, reach out to us. Shoot me an email if I can be of assistance.

David Boyes, President, Today’s Class

David is a business leader with extensive experience in helping organizations drive strategies and improve outcomes through technology implementation. He is an expert in end-to-end management of sales, deployment, and post-delivery operational achievements. As President of Today’s Class, Dave’s focus is helping the automotive aftermarket think differently about people development and training for faster, measurable results over traditional methods.

Before Today’s Class, David held positions at UPS, Accenture, Oracle, and ABB. Leveraging his extensive technology background and leadership experience, he is ready to help shop owners and technicians improve how they learn and quickly demonstrate how this new method can positively impact the auto aftermarket industry. David holds a Bachelor of Science in Industrial Engineering from Kettering University and an MBA from Purdue University. Outside work, David enjoys spending time with his wife and two kids in Davidson, North Carolina.

Comments are closed.