While some aftermarket suppliers are wrangling with offshore manufacturing concerns, one company already has control of its supply chain

Richmond, Va.—With well-documented, pandemic-induced supply chain snarls, many companies have been looking for avenues to bring manufacturing back to their home turf here in the U.S. Interest in onshoring, or reshoring, has accelerated in recent years, not only due to the impact of Covid, but also tariffs imposed by then-president Donald Trump, which remain in play with the Biden Administration.

And according to MEMA Aftermarket Suppliers’ president and CEO Paul McCarthy at a recent industry event, suppliers are also wondering where — and when — they should shift their manufacturing from one country to another based on changing population demographics as their production demands increase: Where will the global workforce talent pool be in coming years as birth rates diminish in some countries? These are just a few of the challenges facing the industry today.

One company, however, does things a little differently. John Paul Amalfe, president of Momentum U.S.A., Inc., said his family-owned, vertically integrated business avoids those handwringing supply chain uncertainties by manufacturing all of its products in the U.S.

“We can out-hustle the global competition and get our products to market quickly. We believe in North American manufacturing and we can win that battle with innovation, technology and automation. We can compete with anybody that’s manufacturing outside of North America,” he told Aftermarket Matters Weekly.

“The global supply chain isn’t sustainable — we’re very bullish on making it here. Being able to control your supply chain like we do is also part of our strategic advantage. We don’t have to wait and wonder about shipping containers arriving on time, or not, from the Middle East or rounding the Horn of Africa. We’re not beholden to any of that and we pride ourselves on our high fill rates.”

U.S.-based manufacturing in company DNA

Amalfe’s grandfather launched the family business in 1945 with a $5,000 loan to jumpstart a single-bay service garage in Elizabeth, N.J. His three sons would go on to grow the retail business by expanding its reach within the local community with auto repair and tire sales. Upon completing college, Amalfe, with his two cousins (partners) then helped lead the family’s third generation into the auto parts distribution sector, eventually acquiring its first manufacturing plant in 1988.

Since then, a series of acquisitions and the construction of new facilities have built Momentum U.S.A. to what it is today: a manufacturer and distributor of exhaust systems, cabin air filters, brake pads and other friction products. The family’s fourth generation is now active in the company with 600 employees, three manufacturing plants, a global distribution center and 15 company-owned distribution centers.

All of Momentum’s family group of companies’ products are sold under its own brands and private label, which includes customers such as First Brands Group, Fram, AutoNation and O’Reilly Auto Parts (AutoPartSource/Momentum USA was just recently awarded — for the second consecutive year — O’Reilly’s Sales & Service Award as its supplier for the O’Reilly MicroGard and HEPA Cabin Air Filter lines).

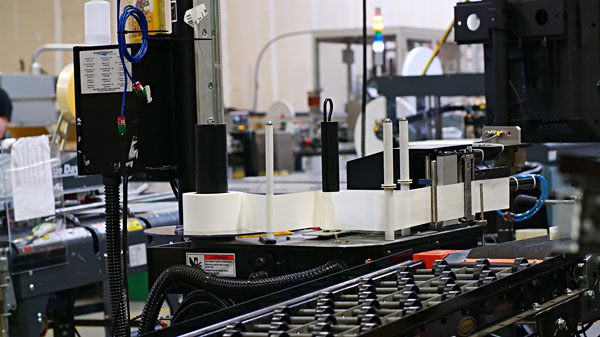

“We’ve invested heavily in cabin filter manufacturing equipment and we’ve been producing them since 2019 with a new facility in Richmond, Virginia,” said Amalfe, adding that prior to producing cabin air filters, Momentum sourced all of them offshore. As demand continued to grow, however, Momentum realized it had to bring the filter manufacturing in-house. “We had to near-shore it, because we didn’t want to be dependent on global imports.”

He expanded by saying the company realized that importing all of its cabin air filters was going to be complex, and was only to become more complex, largely due to parts proliferation and long supply chain demands. Reshoring manufacturing to the U.S. had numerous benefits, from hands-on control of product formulations to quality control.

In order to do that, Amalfe noted it was imperative to automate production to ensure consistency of product. “Compared to other cabin filter manufacturers, who might use 20 to 40 people in production, we accomplish it with three or four people.” And Momentum’s cabin air filter business has “grown immensely,” requiring two full shifts to satisfy three new lines in addition to its original line.

“I like to think of us as a very entrepreneurial company that’s quick on its feet and has a very good feel for what’s happening in the marketplace — from the installer to the biggest retailer in the country. It enables us to have unique insight as to what the technician, WD, large retailer or co-man is looking for.

Market feedback and R&D

The original service and installation facility from 1945 still exists today, and also serves as an R&D center. “We get a lot of feedback on our products, and what the consumer is asking about regarding product and repairs. We also have a distribution group with 15 facilities that sells to direct to installers, so we get first-hand knowledge and input from all of our salespeople who call those technicians every day. It really helps us in our product development.”

Amalfe added that Momentum also performs a “tremendous amount” of fieldwork many of its WD partners. “The more we’re calling on technicians with our products — whether it’s through our own distribution group or partners — the more we’re locked in on feedback.

“We’re like a speedboat that can quickly change course versus a cruise ship that can take a long time to navigate a turn. And we’re winning the battle on the streets.”

Comments are closed.