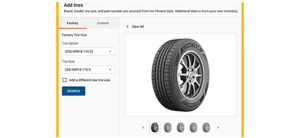

The new Auto34R Tire Changer is designed to service the broadest range of assemblies, while also reducing the opportunity for wheel damage through operator error

St. Louis—Hunter Engineering Company is introducing the new Auto34R Tire Changer, designed to service a broad range of assemblies, while also reducing the opportunity for wheel damage through operator error.

The Auto34R’s speed and ease of use derive from its telescoping chassis that brings the wheel to the rollers and tool head. The new mechanism clocks the rollers and tool head to match the curve of the wheel. Direct rim tracking lowers the stress on beads during mount and demount cycles, saving operator time and reducing the risk of wheel damage.

For shops with space constraints, the compact sliding chassis reduces the need for floor space. Similarly, the bead press arm is center-mounted for a smaller swing radius. The new chassis also eliminates many moving parts, delivering efficient operation over a long service life.

The new model’s electric actuation and three-button control panel provide for simple, smooth and responsive adjustments, saving time, and the risk of damage from crashing rollers into wheels.

“The Auto34R is so easy to operate because diameter changes are so simple to make precisely,” said Jim Hudson, Hunter tire changer product manager. “It’s a great machine for shop owners, too. The unique design eliminates many common tire changer wear points like cables, telescoping arms and locking cylinders, all while reducing the floor space needed to install it.”

For additional information, visit www.hunter.com or contact Maddie Laviolette, marketing analyst and communications specialist, Hunter Engineering Company, 314-716-0380. For more information, contact a local Hunter representative at https://www.hunter.com/contact

Comments are closed.