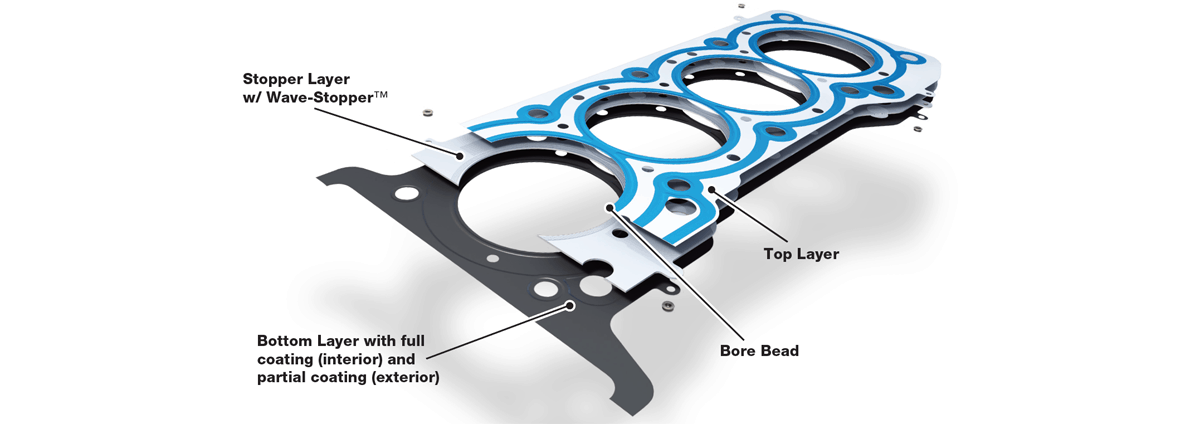

The design uses topography within the gasket structure to create a uniform seal despite severe service environments

Maumee, Ohio—Dana Incorporated has added Victor Reinz Wave-Stopper multi-layer steel (MLS) gaskets to its aftermarket portfolio, featuring Dana-patented technology designed to address the increased sealing requirements of head gaskets in today’s light and commercial diesel engines and forced-induction vehicles.

The Victor Reinz Wave-Stopper design uses topography within the gasket structure to create a uniform seal despite severe service environments. The varied bead height between bolt spans results in more uniform sealing stress at the combustion opening, and this uniformity results in less bore distortion and improved piston ring seal.

They are manufactured with full-hard stainless steel and premium FKM coatings to help ensure enhanced fluid sealing and performance. Its technology helps distribute the load balance between combustion and fluid seals, while allowing for highly uniform loading of stress within diesel engines, resulting in reduced oil consumption, bore distortion, and overhead cam distortion. The Wave-Stopper layer acts as a secondary combustion seal, and because the materials utilized feature both plastic and elastic characteristics, they can be matched precisely to each gasket’s unique working environment.

Comments are closed.