The steel is based on the HYBRIT technology, which replaces coal with hydrogen in the reduction process, powered by fossil-free electricity

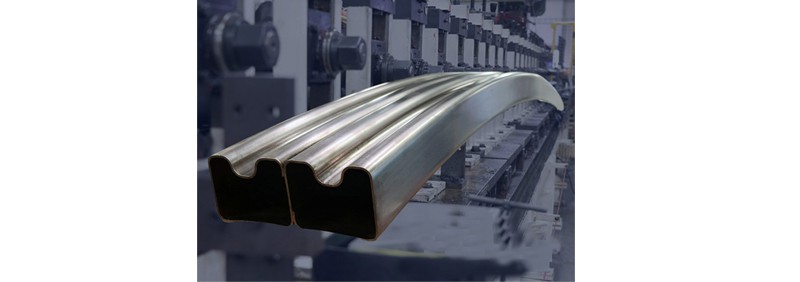

Grand Haven, Mich.—Shape Corp., a global tier-1 supplier, has announced the world’s first roll-formed, production-intent martensitic steel bumper made with SSAB’s fossil-free steel material utilizing HYBRIT technology. Shape is the first automotive company to collaborate with SSAB in using sustainable material in the development of this type of automotive component.

SSAB´s fossil-free steel is based on the HYBRIT technology, which replaces coal with hydrogen in the reduction process, powered by fossil-free electricity. The resulting product is virtually fossil-free.

SSAB aims to produce the steel at a commercial scale in 2026. Shape has conducted rigorous testing, including bendability, fracture characterization, material toughness, delayed fracture testing, and welding evaluations that have shown the fossil-free steel does not compromise material properties or performance.

The roll forming process is also considerably more sustainable when compared to other forming processes, such as hot and cold stamping, due to the significant increase in material utilization.

This process not only enables the usage of the highest strength materials, but also promotes efficient section design to optimize the usage of the material. The use of fossil-free steel with high material utilization and efficient use of high strength material creates an exceptionally sustainable manufacturing solution.

“We are thrilled to take this significant step toward applying this steel on vehicles, marking a new era in sustainable manufacturing,” said Brian Oxley, Project Manager at Shape Corp. “Our material characterization activity ensures that the performance of this fossil-free steel matches that of the incumbent steelmaking process. Considering the full scope of emissions in the steel making and part production processes we calculate a savings of over 10.74 kg CO2 (85.7%) for each bumper beam produced with this steel compared to a part made from conventional steel. Those savings can be closer to 20 kg per part when compared to a stamped bumper of similar performance. Those savings will continue to increase as emissions from both processes are reduced further”

The company has outlined an ambitious timeline for its sustainability journey: by 2025, Shape aims to reduce energy usage by 30% in all its plants around the globe. This step will be followed by achieving carbon-neutral operations worldwide by 2030, powered by 100% renewable energy.

Comments are closed.